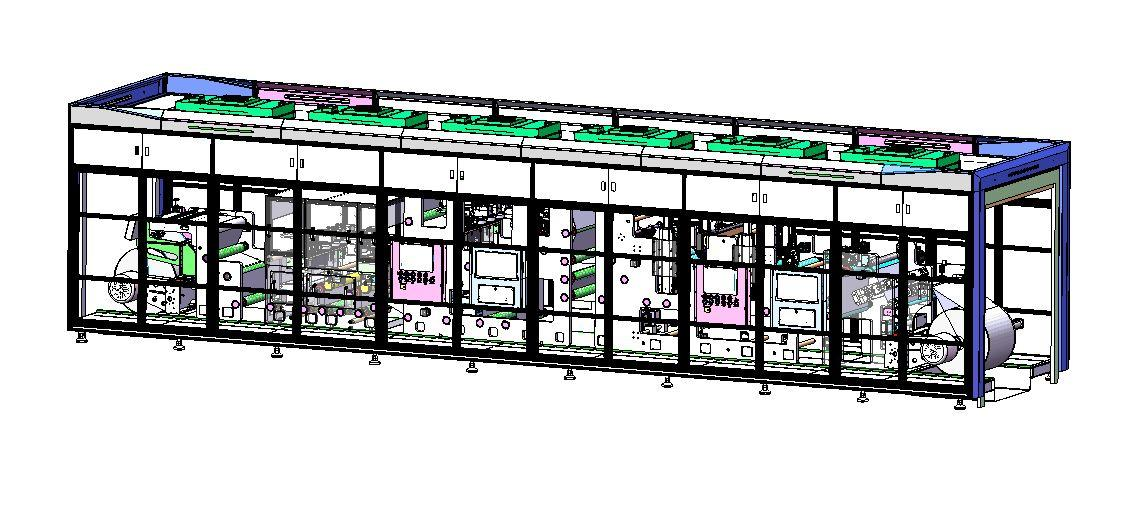

(1)线深10±2.5um

(2)线宽100420un

(3)问距1-1.540.1mm

(4)生产速度18-45m/min

(5)来科最宽750mm

(6)测试生产违度5m/min,振镜速度35m/s

Line depth: 10 ± 2.5 micrometers (um)

Line width: 100-420 micrometers (um)

Pitch distance: 1-1.54 centimeters (cm)

Production speed: 18-45 meters per minute (m/min)

Maximum width of the line: 750 millimeters (mm)

Test production speed: 5 meters per minute (m/min), galvanometer mirror speed: 35 meters per second (m/s)

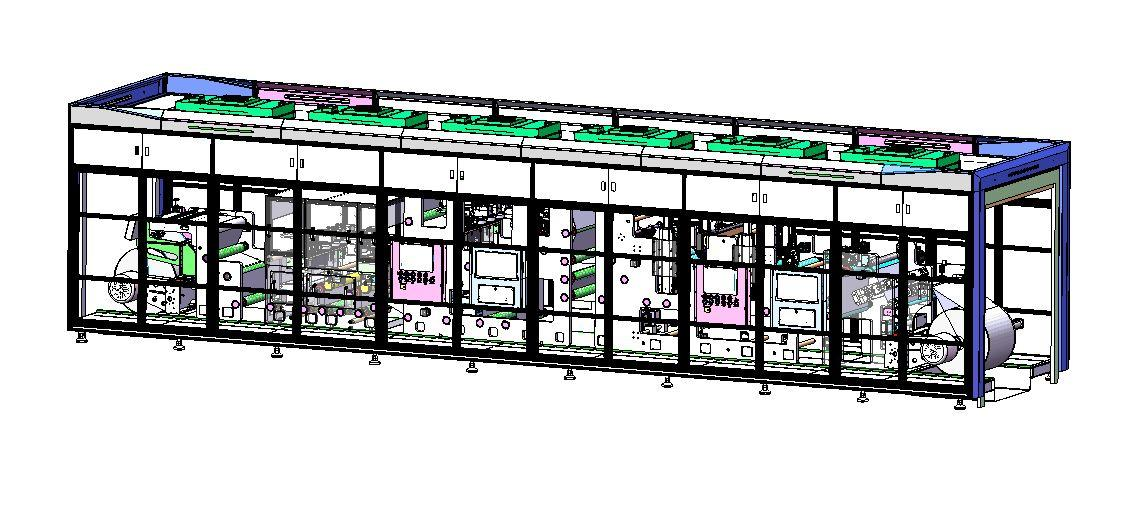

功能特点:

1、在负极上直接刻蚀竖直沟情,可提供最有效的毛细管传输,赠加电电解液浸润效果和速度,可以降低电极的孔隙与曲度,提高有效锂离子扩散系数,并且形成沟槽存储电解液,从而提高电池循环保持率及降低电池内阻,减少负极析锂情况。

2、激光物理划线,提高电池充放电倍率,电池容量和循环寿命

Functional features: 1. Directly etching vertical grooves on the negative electrode can provide the most effective capillary transmission, increase the electrolyte infiltration effect and speed, reduce the porosity and curvature of the electrode, improve the effective lithium ion diffusion coefficient, and form grooves to store the electrolyte, thereby improving the battery cycle retention rate and reducing the battery internal resistance, and reducing the lithium deposition on the negative electrode. 2. Laser physical scribing can improve the charge and discharge rate, battery capacity and cycle life of the battery.