本设备主要用于动力锂电池卷绕工艺的正、负极极片成型。卷状极片来料经激光切割出需要的极片形状,自动一分为二分条收卷。该设备自动化程度高,模块化设计,更换型号灵活,相对于五金模切机换型成本低,节省模具成本,效率更高。

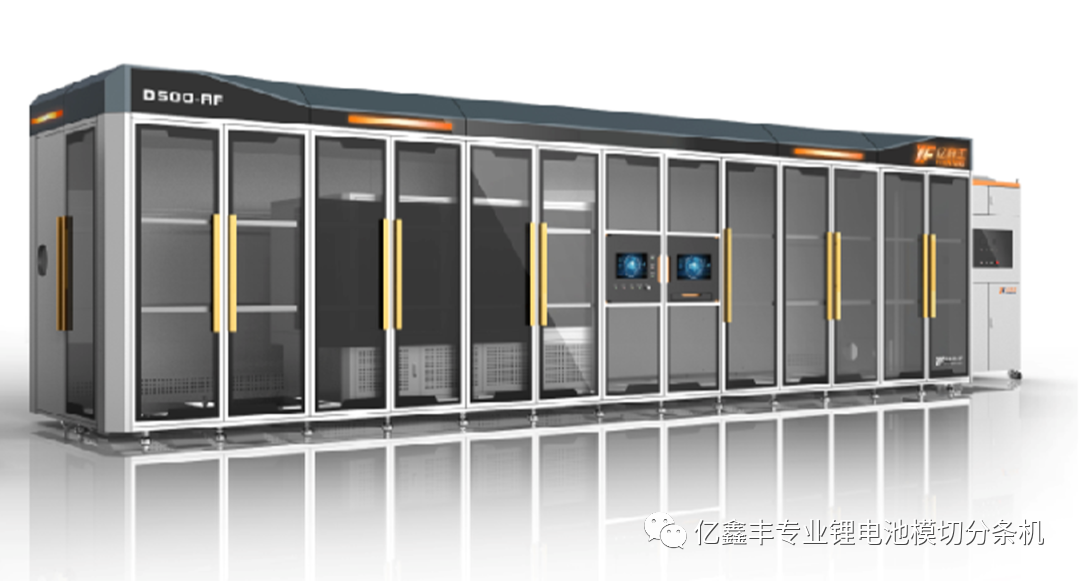

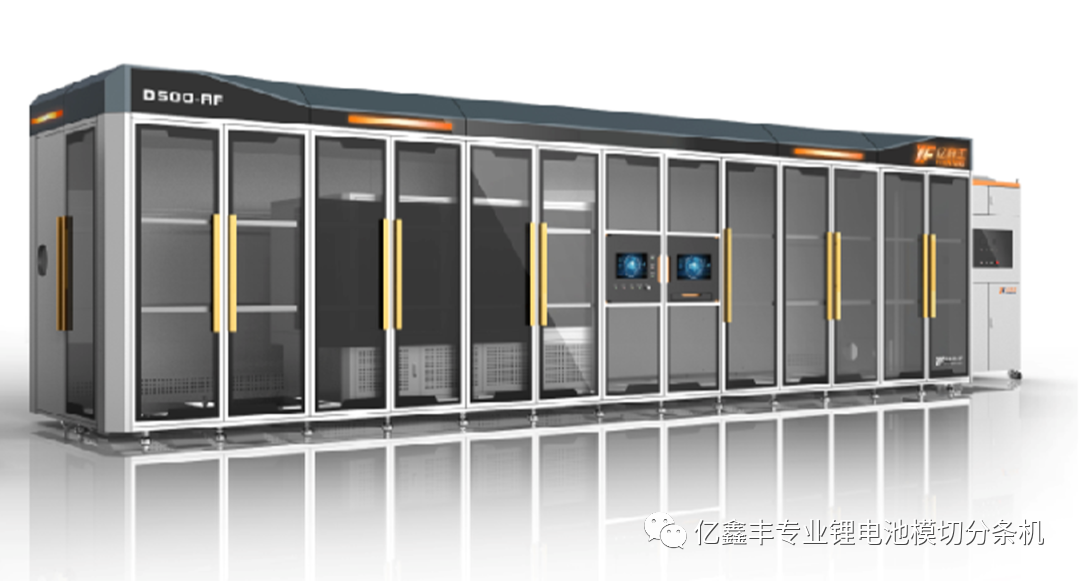

机器型号:J500D-AF

最大料宽:500mm

模切速度:≥60m/min

极片成型精度:±0.2mm

毛刺精度:≤12um

功能特点:

Ø 高速激光切割效率60m/min -200m/min,极耳间距精度 ≤±0.2mm;

Ø 各区域除尘系统及监控系统,实现设备内部粉尘达到万级标准;

Ø 激光变频控制,避免过切或切不断,有效控制毛刺及热影响区熔珠 大小,一体化设计,场地、人力成本降低3~5倍。

Ø High-speed laser cutting efficiency 60m/ min-200m /min, ear spacing accuracy ≤±0.2mm;

Ø Dust removal system and monitoring system in each area, to achieve the dust inside the equipment to reach 10,000 level standards;

Ø Laser frequency conversion control, avoid over-cutting or continuous cutting, effectively control burr and heat affected zone bead size, integrated design, site and labor costs reduced 3~5 times.

机器型号Machine type | 最大料宽Material width | 速度 speed | 成型精度 Molding accuracy | 热影响区Heat-affected zone |

J500D-AG | 700mm | 60-200m/min | ±0.2mm | ≤100μm |