该设备适用于动力锂电池卷绕工艺的正、负极极片多极耳裁切成型。有恒张力自动送料、EPC纠偏、五金模模切成型(自动落废)、自动测长、打孔(标记)、自动收卷等功能。

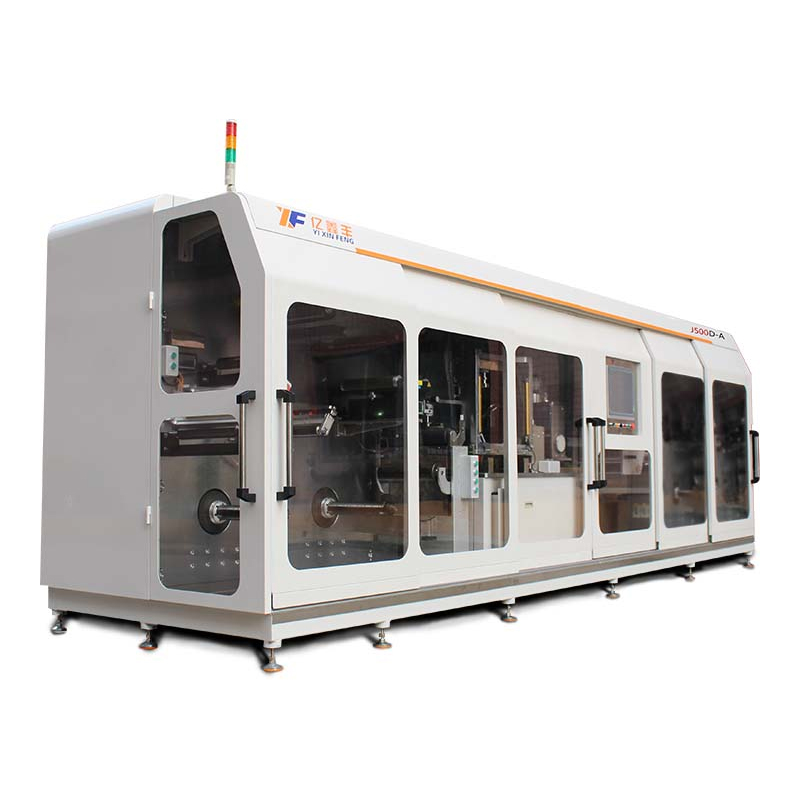

高速五金模模切机型号:J500D-A

The equipment is suitable for cutting and forming positive and negative multipole lugs

in the winding process of power lithium battery. There are constant tension automatic

feeding, EPC correction, metal die cutting molding (automatic waste), automatic length

measurement, drilling (marking), automatic winding and other functions.

High speed hardware die cutting model number: J500D-A

高速五金模模切机性能特点:

●先进的设计理念,确保产品的安全性,可靠性;

●采用轻量化碳纤维辊筒,使辊筒重量由2.8kg降至0.5kg,为高速模切提供了有效的技术支撑;

●自动化程度高,具有自动接带功能;

●多纠偏设计,提高成型极片尺寸精度;

●模具具有快换功能;

●模座移动机构:根据物料状况,模座可以自动调节,提高极片尺寸精度;

●高精度模具,确保模切次数及模切质量;

●模具自冷却功能及气缓冲功能,有效提高模具使用寿命;

●极片牵引采用DD马达直连驱动,减少中间环节传动误差,尺寸精度可以控制在±0,2mm以内;

●极片分条:采用特殊设计的分条机构,不掉粉,毛刺小,精度高;

●非接触式除尘,降低粉尘的二次污染,以及有效的避免毛刷刷粉对极片的伤害;

●易产生粉尘处加装独立吸尘装置(接带处、模切处),大幅度降低粉尘污染的发生;

●设备具备扫码功能,将扫码信息与极组信息(正负极片、极片状态信息等)、人员信息、

环境信息、设备信息等绑定,并保证二维码与对应极组各信息的一致性,传送至MES。

High speed metal die cutting machine performance characteristics:

● Advanced design concept to ensure product safety and reliability;

● Using lightweight carbon fiber roller, the weight of the roller is reduced from 2.8kg to 0.5kg, which

provides effective technical support for high-speed die-cutting;

● High degree of automation, with automatic taping function;

● Multi-deviation correction design, improve the dimensional accuracy of the forming pole;

● Mold with quick change function;

● Mould holder moving mechanism: according to the material condition, the mould holder can be

automatically adjusted to improve the dimensional accuracy of the pole sheet;

● High precision mold to ensure the number of die cutting and die cutting quality;

● Mold self-cooling function and gas buffer function, effectively improve the service life of the mold;

● The pole plate traction is driven by DD motor directly, reducing the transmission error of the

intermediate link, and the dimensional accuracy can be controlled within ±0,2mm;

● Pole sheet slitting: Special design slitting mechanism, no powder, small burr, high precision;

● Non-contact dust removal, reduce the secondary pollution of dust, and effectively avoid the

damage of brush powder to the pole sheet;

● Install an independent dust suction device (belt connection, die cutting) where dust is easy to

produce, greatly reducing the occurrence of dust pollution;

● The device has the function of scanning code, and the scanning code information and pole group

information (positive and negative electrode pieces, electrode piece status information, etc.),

personnel information,

Bind environment information, equipment information, etc., and ensure the consistency of the

two-dimensional code and the information of the corresponding pole group, and transmit to MES.